Kawasaki Kisen Kaisha, Ltd. (“K” LINE) and Nippon Gas Line Co., Ltd. (Nippon Gas Line) are pleased to announce the agreement to establish a marketing company for the purpose of providing the seamless and efficient integrated liquefied CO2 transportation service for carbon dioxide capture and storage (CCS) projects over the boundaries.

The Japanese government is advancing the development a business environment to initiate CCS projects by 2030 in its “Basic Policy for Realizing of GX” (*1). They plan to support the research and business development to scale up the CCS value chain at the same time to cost reduction by introducing hub and cluster structure. In relation to its development, cross-border CO2 transportation and the establishment of integrated transportation system by combination of various sized liquefied CO2 carriers has been studied.

“K” LINE group is promoting a variety of initiatives to support the low-carbon and carbon-free of its own operations and society in accordance with its long-term environmental policy, “K” LINE Environmental Vision 2050. “K” LINE will start operation of liquefied CO2 carriers for Northern Lights, the world’s first full-scale CCS project this year. “K” LINE set up a dedicated team for ship management of liquefied CO2 carrier in “K” LINE LNG Shipping (UK) Ltd. and is working to realize safe and reliable operation.

Nippon Gas Line, the only operator specializing in domestic LPG carriers, has accumulated extensive knowledge and experience in the operation, cargo handling, and ship management of pressurized gas carriers for over 60 years. Regarding CCS projects in particular, Nippon Gas Line is undertaking operation and ship management of a liquefied CO2 carrier and developing operation and cargo handling technology for low-temperature and low-pressure liquefied CO2.

“K” LINE and Nippon Gas Line determined to take initiatives in liquefied CO2 shipping for CCS projects. This collaboration of both companies will provide safe, stable and high-quality liquefied CO2 seamless transportation services by leveraging knowledge and experience together. Both companies will contribute to the realization of a carbon-neutral society through CO2 shipping.

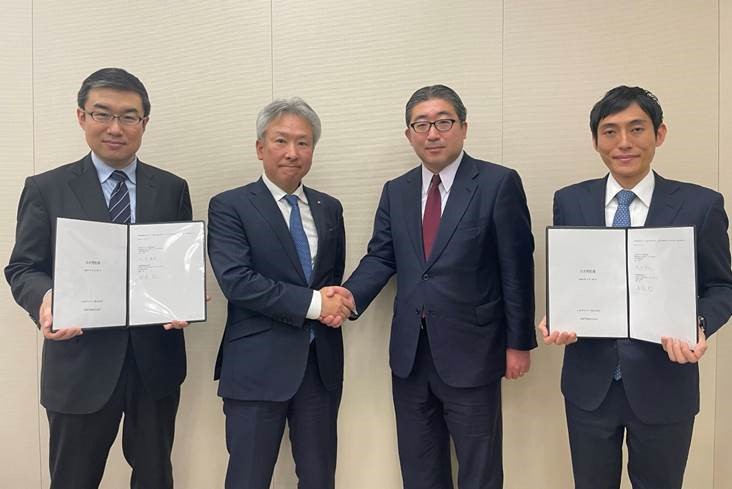

“K” LINE:Jun Sasaki (General Manager, Carbon-Neutral Promotion Group)

“K” LINE:Satoshi Kanamori (Managing Executive Officer)

Nippon Gas Line:Yasuhiro Muramatsu (President)

Nippon Gas Line:Kazuhisa Ishizaki (Senior Managing Director)

*1 “Basic Policy for the Realization of GX” (Released as of Feb 10th, 2023 by METI (Ministry of Economy, Trade and Industry, JAPAN) :