Kawasaki Kisen Kaisha, Ltd. (“K” LINE) is pleased to announce that its commencement provision of marine data to the Japan Coast Guard (JCG). This data, sourced from monitoring systems onboard the merchant vessels of Mitsui O.S.K. Lines, Ltd. (MOL), Nippon Yusen Kaisha (NYK) and “K” LINE is now being shared through the Ship IoT data sharing platform IoS Open Platform (IoS-OP) managed by Ship Data Center Co., Ltd. (ShipDC).

In the past, the JCG relied on MOL, NYK, and “K” LINE for voluntary submission in marine data, which they then integrated manually. The IoS-OP gathers data from approximately five hundred ships operated by MOL, NYK and “K” LINE meaning it is one of the world’s largest ships IoT databases. Now, it has become possible to comprehensively supply the large body of detailed operational data gathered by the IoS-OP. The JCG plans to use this extensive data to enhance tidal current prediction accuracy, thus contributing significantly to marine safety and their work efficiency.

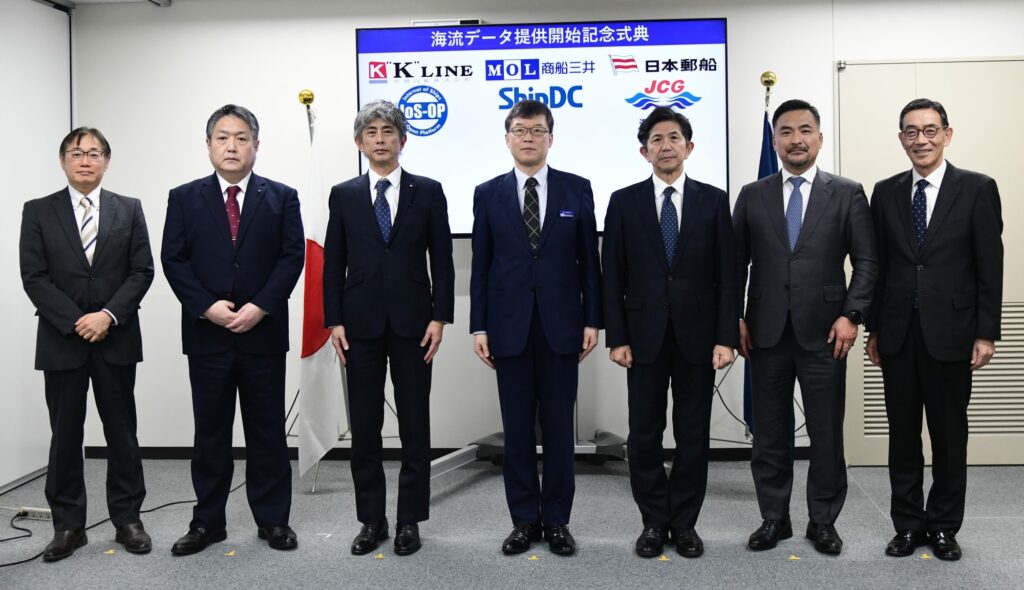

Mr. Yasuhiro Ikeda – Representative Director and President, ShipDC

Mr. Shingo Kameyama – Managing Executive Officer, “K” LINE

Capt. Hisaya Higuchi – Managing Executive Officer, NYK

Mr. Masayuki Fujita – Director General of Hydrographic and Oceanographic Department, JCG

Mr. Tomoyuki Koyama – Chairman, IoS-OP Consortium

Mr. Makoto Yamaguchi – Executive Officer, MOL

Mr. Hiroaki Sakashita – Representative Director and President & CEO, ClassNK

“K” LINE is committed to advancing data utilization by sharing shipping data via IoS-OP. This initiative not only contributes to the maritime industry’s growth but also aligns with our ongoing efforts to enhance navigation and cargo operation safety. Moreover, it reflects our dedication to environmental stewardship in an increasingly digital era.

In celebration of centralized management of marine data, a ceremony was held on January 26th with the attendance of relevant stakeholders.