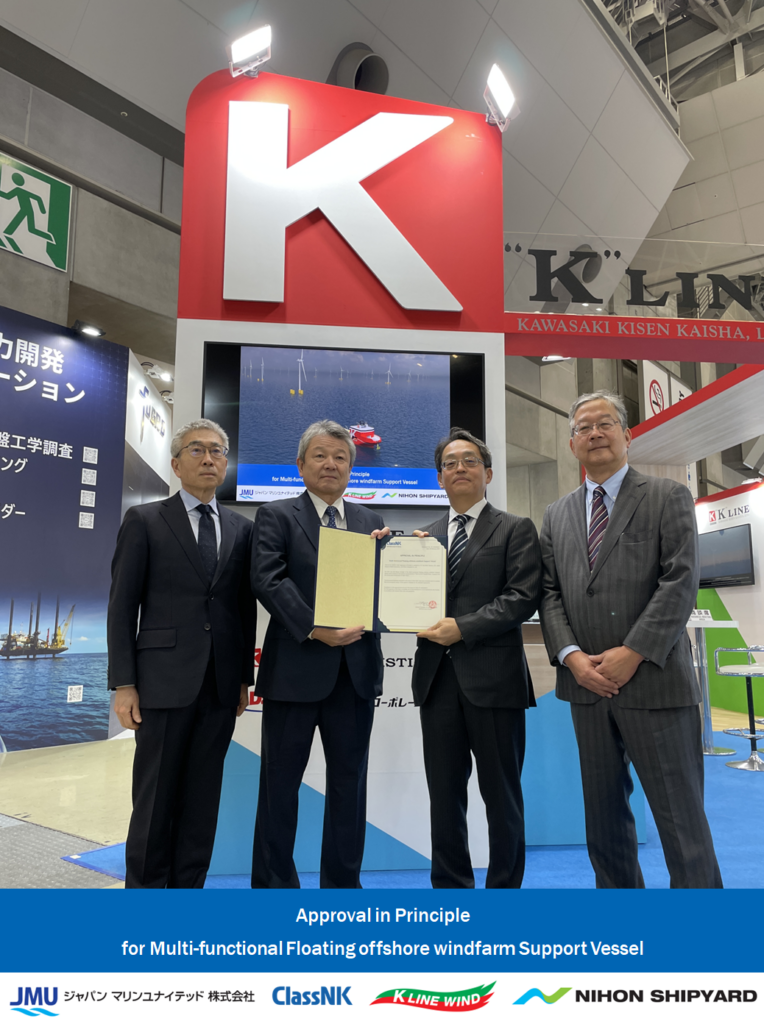

Approval in Principle (AiP) from Japanese Classification Society Class NK for the design concept of the Multi-functional Floating offshore windfarm Support Vessel

“K” Line Wind Service, LTD. (“K” Line Wind Service), a joint venture of Kawasaki Kisen Kaisha, Ltd. and Kawasaki Kinkai Kisen Kaisha, Ltd., together with Japan Marine United Corporation (Japan Marine United) and Nihon Shipyard Co., Ltd. (Nihon Shipyard) have been jointly granted Approval in Principle (AiP) *¹ from Nippon Kaiji Kyokai (ClassNK) for the design concept of the multi-functional floating offshore windfarm support vessel (MFSV).

The development of this design concept is subsidized by the New Energy and Industrial Technology Development Organization (NEDO) as a part of Green Innovation Fund Project “Technology development project for basic manufacturing and installation cost reduction for floating wind turbines”. *²

The development of floating offshore wind is expected to take an important and key role in the achievement of the carbon neutrality by 2050, especially in Japan where shallow water area to develop the bottom-fixed offshore wind turbines is limited.

The installation of floating offshore wind turbines always required mooring works by vessels, with the whole mooring system composed of an anchor, a mooring chain, and a fiber rope. “K” Line Wind Service has been pursuing the study on the most effective mooring method and the most suitable vessel design for such mooring work together with Japan Marine United and Nihon Shipyard. Finally, we completed the design concept of MFSV and obtained AiP from ClassNK.

This MSFV is designed to perform whole mooring works efficiently for floating offshore wind turbine installation, like “transportation of mooring system”, “deploying mooring system on the seabed”, “anchor tensioning”. On top of such primal functions, the uniqueness is multifunctional concept. This MFSV is designed to provide various vessel solutions in each phase of an offshore wind projects such as “Survey”, “Transportation”, “Construction”, and “Operation & Maintenance”. (multifunction concept of MFSV is currently under process of patent application)

“K” Line Wind Service is determined to contribute to Low-carbon and decarbonization of society by pursuing the provision marine and vessel solution including the design concept of MFSV for mass production and cost reduction of offshore wind power generation.

From left :

Hirohiko Yanagita, Managing Officer of Japan Marine United Corporation

Toshiyuki Shigemi, Senior Executive Vice President of ClassNK

Teruki Kuramoto, President of “K” Line Wind Service, Ltd.

Yoshinori Maeta, President of Nihon Shipyard co., Ltd.,

*¹ AiP, which stands for Approval in Principle, is a scheme for the examination of plans and documents based on the rules for products in the early design stage to confirm their technical feasibility from the viewpoint of the rules. (Source: Nippon Kaiji Kyokai, ClassNK )

*² about adoption of the Joint Project “Mass-Production and Cost Reduction of Floating Offshore Wind Installation” as Green Innovation Fund Project “Cost Reductions for Offshore Wind Power Generation Project”

Related Press Release of Green Innovation Fund Project

Joint project on “Mass-production and Cost Reduction of Floating Offshore Wind Installation” adopted as Green Innovation Fund (On January 21, 2022)

https://www.kline.co.jp/en/news/carbon-neutral/carbon-neutral-20220121.html