Engineering Advancement Association of Japan

Kawasaki Kisen Kaisha, Ltd.

Nippon Gas Line Co., Ltd.

Ochanomizu University

The christening and handover ceremony for a liquefied CO2 transportation demonstration test ship was held today, November 28, 2023, at the Shimonoseki Shipyard of Mitsubishi Heavy Industries, Ltd. (Shimonoseki city, Yamaguchi).

The construction of the demonstration test ship was completed today, and the ship will transport liquefied CO2 for the CCUS R&D and Demonstration Related Project, the Large-scale CCUS Demonstration in Tomakomai, the Demonstration Project on CO2 Transportation, the R&D and Demonstration Project for the Marine Transportation of CO2 (the “Demonstration Projects”) which are being conducted by NEDO.

The demonstration test ship was named “EXCOOL” by Mr. Masazi Sasayama, Deputy Director of Carbon Management Division Natural Resources and Fuel Department Agency for Natural Resources and Energy of Ministry of Economy, Trade and Industry, who took part in the ceremony along with all those involved in the demonstration project. The vessel was delivered today to Sanyu Kisen (Kobe City) and chartered to Nippon Gas Line Co., Ltd. (Nippon Gas Line)

General Specifications

Cargo tank capacity: 1,450 m3

Overall length: 72.0 m

Breadth: 12.5 m

Draft: 4.55 m

The “EXCOOL” will be operated in this demonstration project with the aim of establishing a technology for the large-volume and long-distance marine transport of liquefied CO2, which will play an important role in the development of Japan’s CCUS (Carbon Dioxide Capture, Utilization and Storage) project.

The use of vessels is an effective way to improve the efficiency of transporting CO2 from capturing sites to remote storage sites. To increase efficiency still further, liquefied CO2 should be transported by large size vessels. “EXCOOL=EX-CO2L” was named with a determination to establish a safe operation technology for transporting low-temperature liquefied CO2, which is suitable for larger vessels.

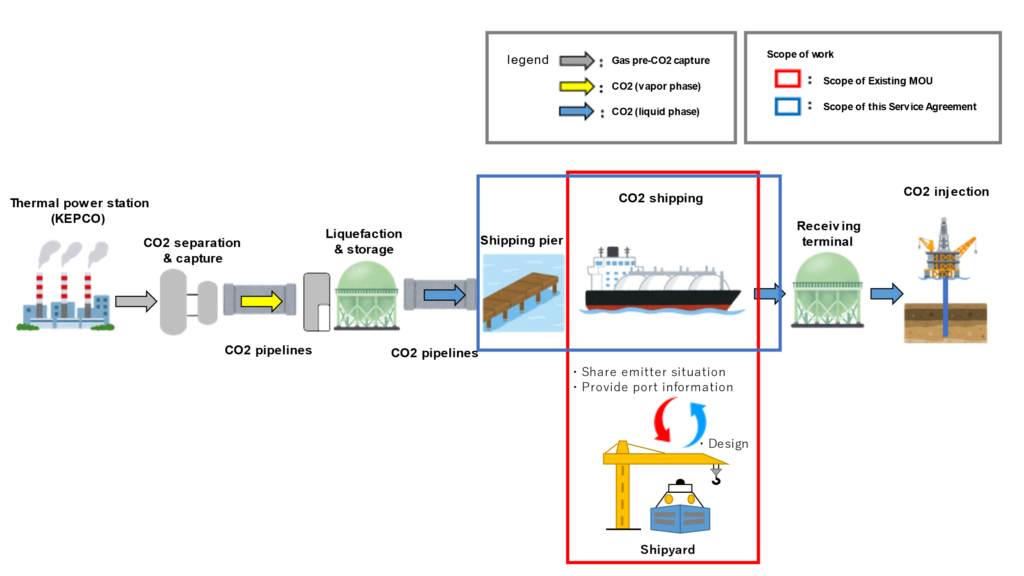

CCUS is regarded as an indispensable technology for achieving carbon neutrality in 2050, and the Japanese government and companies are preparing for it to become fully operational from 2030. Along with these activities, international movements are underway to utilize the abundant overseas CO2 storage capacity potential, including the establishment of the “Asia CCUS Network.” The efficient transport of CO2 captured in Japan to overseas locations by ship will consequently become an essential technology in the future. In this demonstration project, the EXCOOL will be used to verify the techniques for transporting and handling liquefied CO2 in tanks under different transport conditions, with the aim of establishing optimal CO2 marine transport technology in terms of the environment, safety, and economic efficiency.

The roles of each company in this demonstration project are as follows.

Engineering Advancement Association of Japan (ENAA) has been engaged in research and development for the operation of a demonstration ship equipped with a liquefied carbon dioxide ship tank system. It achieved delivery of the demonstration vessel. ENAA will continue to be responsible for the planning, analysis and supervision of the demonstration test in the future.

Ochanomizu University conducts basic research on the control of the state of carbon dioxide (phase changes) and provides the information required for safe transportation.

Kawasaki Kisen Kaisha, Ltd. (“K” LINE) has helped to prepare an operation manual by conducting a risk assessment of the “EXCOOL” using its expertise in operating cryogenic liquefied gas carriers. “K” LINE will continue to contribute to the establishment of safe liquefied CO2 carrier operation technology through its analysis of demonstration data.

Utilizing its expertise in operating coastal gas carriers, Nippon Gas Line will measure CO2 temperature, pressure, flow, and other data while operating the “EXCOOL” to develop optimal transport methods and cargo handling techniques.

With this demonstration project, ENAA, “K” LINE, NGL, and Ochanomizu University aspire to contribute to the realization of a carbon neutral society.

[Related releases]

June 22, 2021: Participation in R&D and demonstration project for CO2 marine transportation

February 2, 2022: NEDO Demonstration Project: The World’s First Demonstration Test Ship for Liquefied CO2 Transportation to be Built

October 7, 2022: NEDO Demonstration Project: Demonstration Test Ship for Liquefied CO2 Transportation has broken ground

March 28, 2023: NEDO Demonstration Project: Demonstration Test Ship

for Liquefied CO2 Transportation has been Launched.