~Promoting the development of CCS-related businesses to realize a carbon-neutral society~

CCS is a series of technologies for capturing carbon dioxide (CO2) emitted from power plants, refineries, and factories instead of releasing it into the atmosphere. The captured CO2 is then injected deep into the ground at a carefully selected and safe site, where it is stored. The CCS is a climate change technology that can achieve significant CO2 emission reductions thereby reducing greenhouse gas emissions which is key to the realization of a carbon neutral society in 2050.

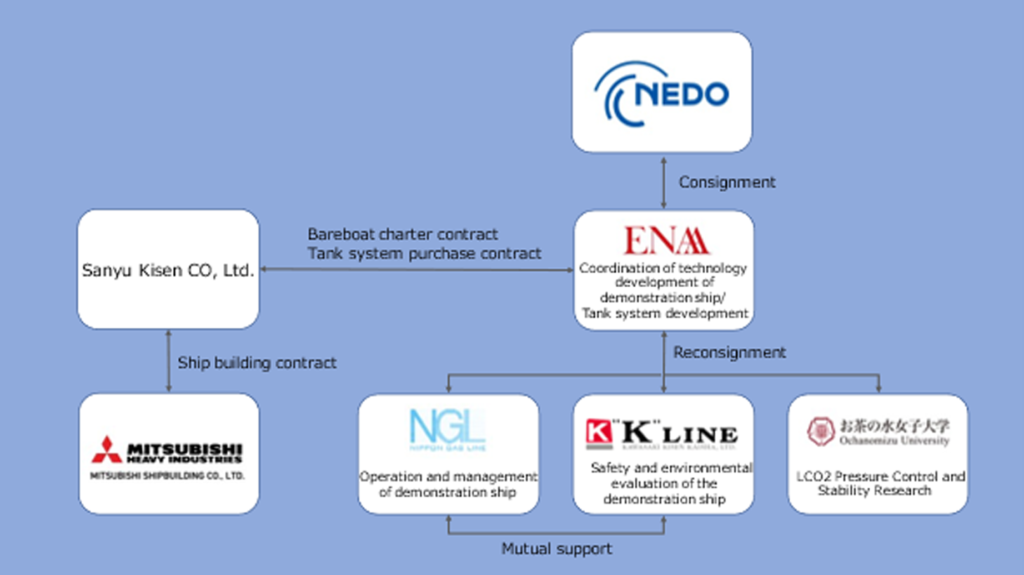

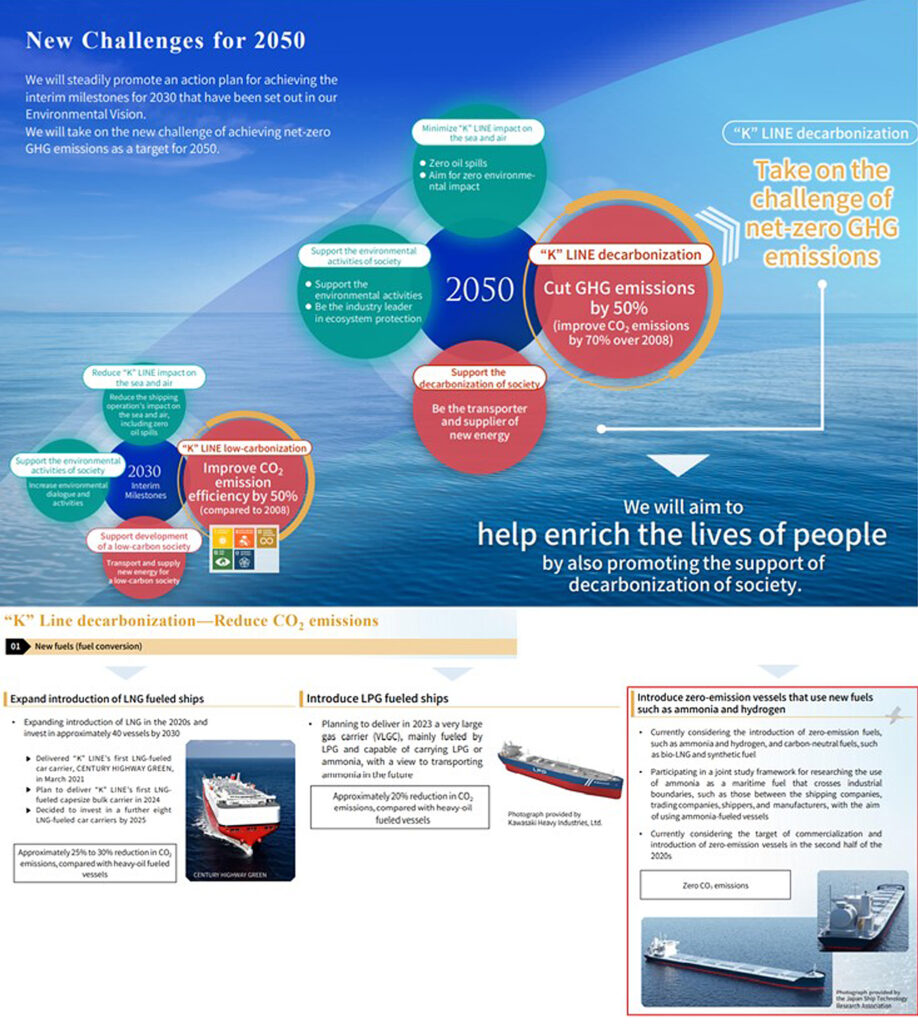

“K” LINE is actively promoting CCS-related businesses. In the demonstration test of an onboard CO2 capture system, “K” LINE successfully separated and captured CO2 from the exhaust gas emitted from the vessel for the first time in the world. The result of the demonstration was achieved with the planned performance. (Note 1) In addition, “K” LINE is participating the demonstration project on CO2 ship transportation by New Energy and Industrial Technology Development Organization(NEDO) and conducting research and development that will contribute to the long-distance and large-scale transportation of CO2 in the future. The liquefied CO2 carrier for the demonstration test is being built as the world’s first demonstration vessel for the CCUS project, and “K” LINE is participating in the development of CO2 shipping technology by utilizing our technology and knowledge of safe operation and safe cargo handling of liquefied gas carriers which we have cultivated over many years. (Note2)

GCCSI was established by the Australian government in 2009 to promote the use of CCS technology worldwide, and currently has members from all over the world, including government, industries, and research organizations. GCCSI conducts surveys on the latest trends in CCS business and technology and holds subcommittee meetings to discuss the launch of international CCS projects in the future.

“K” LINE will keep abreast of the international CCS development and will accelerate its consideration of participation in CCS related business by joining GCCSI. We will continue to contribute to the realization of a carbon neutral society based on the “K” LINE Environmental Vision 2050 (Note 3).

Global CCS Institute Outline

The Global CCS Institute is an international think tank whose mission is to accelerate the deployment of carbon capture and storage (CCS), a vital technology to tackle climate change and deliver climate neutrality and it promotes research, knowledge sharing and awareness raising on CCS related trends. The diverse international membership includes governments, global corporations, private companies, research bodies and non-governmental organizations.